Products

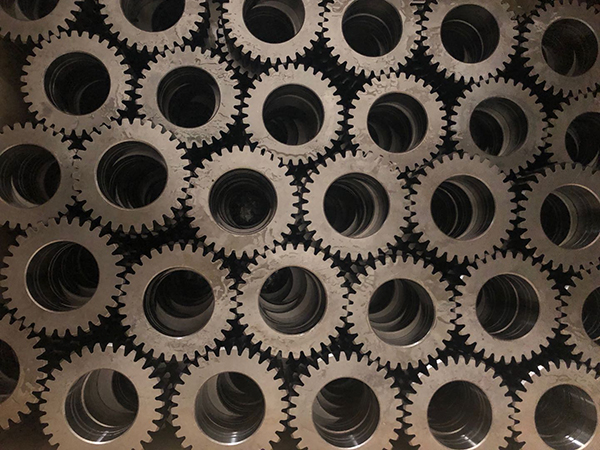

Spur Gears

Spur gears have a cylindrical pitch surface with teeth that are parallel to the axis, Spur Gears are widely used in kinds of application. Teeth treatment include shaping, hobbing and grinding, the Max OD is 1600mm, module from 0.5 to 25. We mainly accept OEM services, most spur gears customized as your drawing or sample.

Product Specifications:

| Material | C45,1045,42CrMnTi,20CrMnTi,2HT200,HT250,QT400-18,QT400-15,Acetal/Delrin,Alloy,Steel,Aluminum,Brass, Bronze, Carbon Steel, Ductile Iron, Gray Cast Iron, Nylo, Plastic, Phenolic, Polycarbonate, Polyester, Stainless Steel etc. |

| Modulus | 0.5-24 |

| Accuracy | DIN Class 6, ISO/GB Class 6, AGMA Class 13, JIS Class 2 |

| Standard | DIN, ISO/GB, AGMA, JIS |

| Heat treatment | Quenching and tempering, gear teeth induction quenching, nitriding, carburizing |

| Application | Automotive, electronics, textiles, printing, packaging, medical equipment, food processing ,wind power, chemical, and pneumatics |

| Shaft length | Max 1600mm. |

Capabilities of Gears:

Item | Internal Gears | External Gears | ||||

Milled | Shaped | Ground | Hobbed | Milled | Ground | |

Max O.D. | 1600mm | |||||

Min I.D.(mm) | 30 | 320 | 20 | |||

Max Face Width(mm) | 500 | 1480 | ||||

Max DP | 1 | 1 | 1 | 1 | ||

Max Module(mm) | 26 | 45 | 26 | 45 | ||

AGMA/ DIN Level | DIN Class 8 | DIN Class 6 | DIN Class 8 | DIN Class 6 | ||

Tooth Finish | Ra 3.2 | Ra 0.6 | Ra 3.2 | Ra 0.6 | ||

Max Helix Angle | ±22.5° | ±45° | ||||